Ultrafast Laser Surface Texturing

Ultrafast laser micromachining

Laser defects for fracture studies

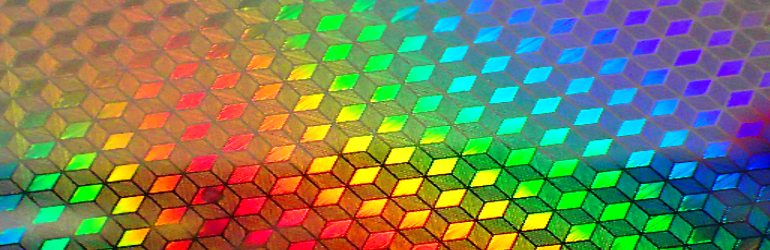

Ultrafast Laser Surface Texturing

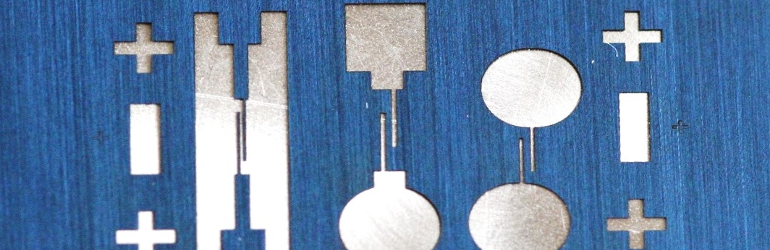

Ultrafast laser micromachining

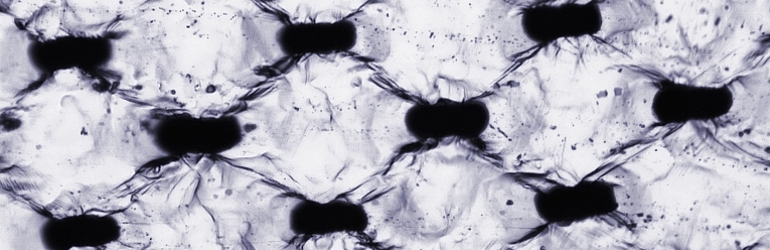

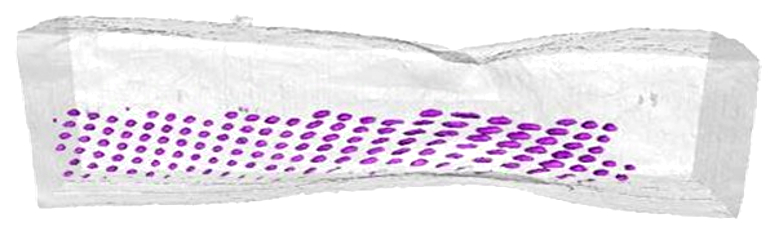

Laser defects for fracture studies

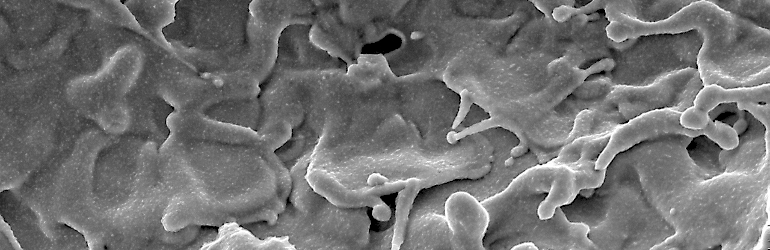

The Weck Lab's interests lie at the intersection of photonics, materials science, chemistry, and surface engineering.

We use ultrafast lasers to texture the surface of materials to control properties such as colours, wettability, chemical reactions, and biocompatibility.

We also use these lasers for high speed micro-machining, fundamental laser-matter interaction studies, and to induce artificial defects (crack and voids) to investigate fracture mechanisms.

More details here!